Smart Storage Solutions: A Closer Look at the Cost of Pallet Racking for Warehouses

Pallet racking systems are essential to any supply chain — many warehouse operations depend on pallet racks. They are sturdy, provide reliable storage and come in many varieties that can be customized to fit a range of specifications. As with any system in your company, understanding the cost of pallet racking systems is vital.

The warehouse racking cost per square foot varies based on several factors, especially the type of pallet system you choose. This guide explores smart storage solutions and looks at the cost of pallet racking for warehouses. It breaks down common pallet racking systems and their benefits and aims to estimate how much pallet racking costs.

What Affects the Cost of Pallet Racking?

Pallet racking is a comprehensive storage solution with various components and accessories that all add to the price. These factors all impact pallet rack costs:

- Rack type: Rack type is one of the biggest contributing factors to the cost of your system. Single-deep pallet racks cost less than gravity flow racks, for example.

- Size: Pallet racking systems can be tailored to warehouse requirements, but generally, the higher and larger your racking system is, the more installation will cost.

- Load capacity: Pallet racks are designed to hold various materials, but if your warehouse typically stores very large and heavy items, you will need a system with a high load capacity per pallet position. In this case, racks are reinforced with extra beams that can hold the weight of heavy loads.

- Material type: Pallet racks come in various materials and finishes that impact the cost. Steel is the most common material for pallet racking systems because it is durable, long-lasting and an excellent load-bearing material. Other materials include wood and aluminum, which are both cost-effective solutions. However, neither has the longevity that steel pallet racking systems offer.

- Layout: The cost of installing a storage system may increase if your warehouse’s layout calls for a custom configuration.

- Accessories: Often, quotes for pallet racking systems are base quotes. That means you will need to factor essential accessories into the price of a complete system. Accessories include safety bars, dividers and wire decking.

- Compliance: While not directly related to the cost of the racking system, adding pallet racking can come with additional expenses related to warehouse regulations, fire safety and other compliance matters.

- Lead time: Rush orders generally cost more, so an easy way to get the best quote for your storage system is to plan ahead.

- Installation costs: Installing a pallet racking system is a specialized job, and safety and compliance are major concerns. It is vital to factor professional installation into your budget or to partner with a supplier who offers in-house installations so you get the best quote for your racking system.

View Our Pallet Rack Solutions

Here’s a quick breakdown of common pallet racking systems, their benefits and an estimate of how much you can expect to pay for each.

Exploring Types of Warehouse Pallet Systems

There are several options to consider before installing pallet racking. For example, to accommodate a higher density of products on the shelf, you may need to compromise when it comes to ease of accessibility. Budget is also a concern for any business. In general, higher density will translate to an increased warehouse racking cost. Keep reading to learn more about pallet rack shelving prices.

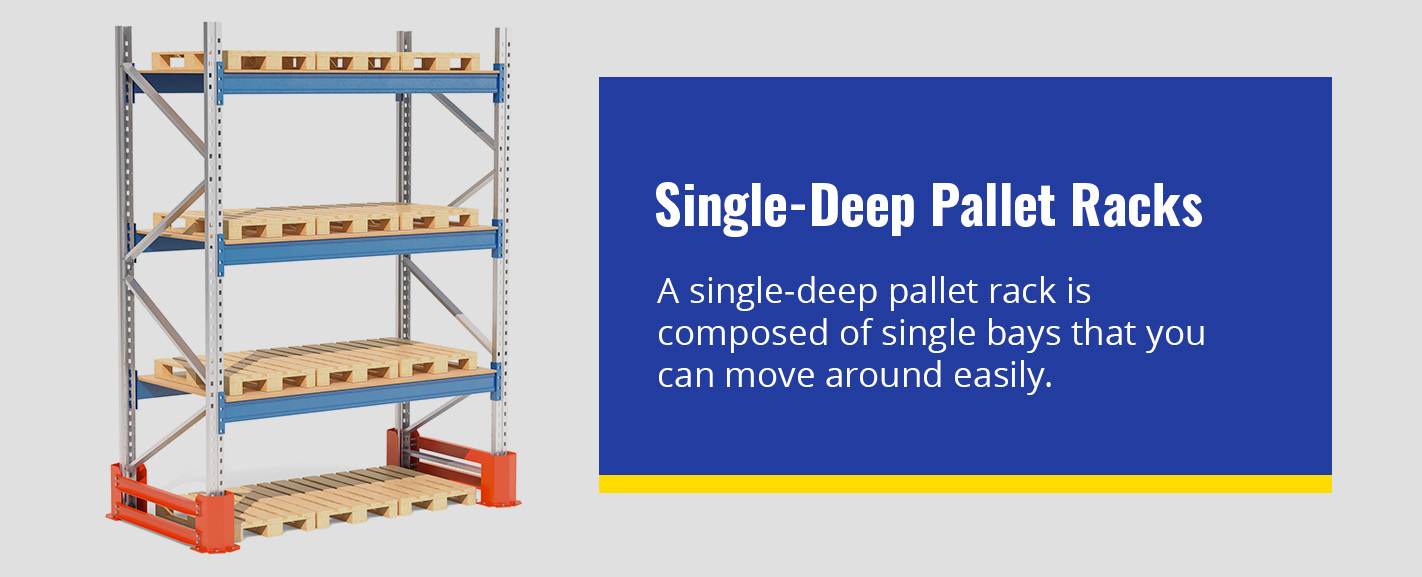

Single-Deep Pallet Racks

A single-deep pallet rack is composed of single bays that you can move around easily. The single-deep racking system is the simplest pallet racking system and is among the most popular storage solutions for small to medium warehouses.

Because single-deep pallet racks are such a straightforward solution, they offer many benefits, including the following:

- Warehouses can store more goods in single-deep pallet racks, making them a more efficient solution than multi-deep racks.

- Staff can easily find and access goods as single-deep racks allow access from both sides.

- Single-deep pallet racks are good storage solutions for small spaces.

- The single bays offer high visibility for forklift operators to ensure safety.

- The low-density design allows easy access to each pallet.

- Because of the straightforward design of single-deep pallet racks, the cost is reasonable, making this system a budget-friendly option.

A single-deep pallet racking system costs approximately $50 to $80 per pallet position, excluding accessories and customization.

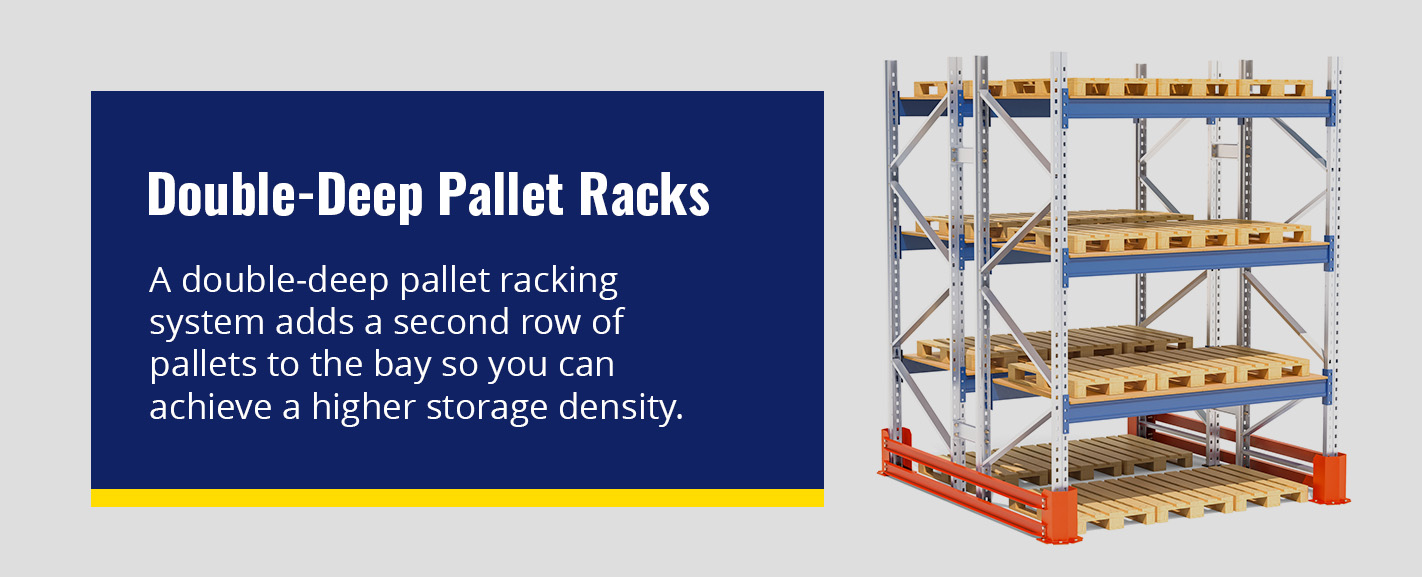

Double-Deep Pallet Racks

A double-deep pallet racking system adds a second row of pallets to the bay so you can achieve a higher storage density and maximize space. This configuration gives you more pallet locations, but visibility and accessibility are slightly less than you can expect from single-deep pallet racks.

Other benefits of double-deep racking systems include:

- Warehouses can hold a higher density of products and optimize the aisle-to-shelving ratio.

- You can eliminate the need to buy or rent more storage space by using the current space more efficiently.

- While accessibility is slightly lower than that of single-deep racks, the difference may not be significant in your warehouse.

- It is easier to keep product lines together with two-pallet deep storage.

- For the increased storage density you enjoy, double-deep pallets are still a cost-effective storage solution.

On average, double-deep pallet racks cost around $80 to $200 per pallet position. Part of the reason that they are more expensive than single-deep racks is that you need to add features like guard rails to double-deep systems. The reduced visibility on higher shelves can be a challenge to forklift operators, and these extra features help ensure safety. Another financial consideration is that you may require a different truck than an ordinary fork truck to access rear pallets.

Gravity-Flow Racks

Gravity flow pallet racking, also called a pallet flow rack system, is an innovative system that relies on gravity to operate. The storage conveyors are designed with downward slopes. Items are loaded onto the top end or rear of the rack, and gravity draws the pallet down to where another forklift will offload the pallets.

These racks are an ideal storage solution for warehouses that move products on a first-in, first-out basis. There are several other benefits of having a gravity flow rack system:

- Gravity flow racks offer a high-density storage solution.

- The system makes it easier to keep track of product turnover. It reduces congestion while loading and unloading and makes organizing and retrieving pallets more efficient. This also translates to lower equipment and labor costs.

- Offer easy access to the products that need to go out first.

- The first-in, first-out system ensures a consistent inventory rotation.

- Gravity flow racks are an ideal solution for saving space and becoming more efficient time-wise and labor-wise.

- You can adjust the system’s shelving according to product sizes.

- Because of increased productivity and storage optimization, the return on investment (ROI) is worth it — especially for larger warehouses.

Estimated Gravity-Flow Pallet Racking Cost

These high-density racks cost an average of $200 to $400 per pallet position. This makes the system more expensive than other pallet racking types initially, but the improved productivity and efficiency can make it worth it.

Understanding the True Cost of Pallet Racking: Beyond the Price Tag

Purchasing a pallet racking system is a straightforward cost, but you also need to consider other factors that can impact your budget.

Cost-Effective Pallet Racking Solutions

Maximizing storage and your warehouse’s efficiency is paramount to operations — as are cost considerations and exploring strategies for getting warehouse racking prices within budget. No matter your warehouse’s needs and budget requirements, there are options to benefit your operations. Because new versus used pallet racking prices may vary greatly, you can find systems at different price points without compromising quality and functionality.

One of the ways you could strike a balance between a cost-effective but practical solution is to consider different buying options. Depending on your needs, you could buy new, used or reconditioned pallet racking systems. Warehouses often purchase brand-new systems for quality and guarantee reasons. However, with the right supplier, you could find used or reconditioned pallet racking systems to suit your budget, so looking into all your options is well worth it.

- New pallet racking systems: As we have seen, new pallet racking systems can cost $5 to $400 per pallet position, depending on the type of rack you choose — minus accessories. Purchasing a new system can benefit your warehouse and give you peace of mind in terms of warranties and insurance. Installing a new pallet racking system comes with a high initial cost but is often a worthwhile investment for larger warehouses.

- Used pallet racking systems: For smaller warehouses, having high-quality storage solutions is no less important, but cost considerations become of utmost importance. In this case, a quality used system is ideal. With the right supplier, you can find used pallet handling equipment, including jacks, uprights, beams, and even rack and post protectors that provide a level of organization comparable to that of new systems.

- Reconditioned pallet racking systems: Reconditioned pallet racking systems are another cost-effective solution. These systems have been repaired in some way, so always go for a trusted supplier to ensure that the racks are up to safety standards.

The Price of Installation and Labor

You may be able to save on the cost of installing a pallet racking system a few ways. Working with a supplier with an in-house installation crew can have a positive effect on your budget. You will often be able to enjoy discounted prices thanks to the cost-effectiveness of self-contained services, and you can be assured of the quality and efficiency of the installation. Other cost-saving avenues include ordering bulk quantities from your supplier and keeping an eye on their clearance sales and other special offers.

Long-Term Racking Equipment Costs: What to Expect

Your storage solution is a long-term investment, and this means additional costs as you maintain your systems or upgrade them as necessary to keep your racking systems durable and safe. By having a proactive maintenance strategy, you can extend the longevity of your pallet racks and avoid the cost of having to repair or replace systems too soon. These various practices can form part of an effective maintenance routine:

- Training staff: The Occupational Safety and Health Administration (OSHA) mandates that all forklift operators must have adequate training. This is primarily to avoid workplace accidents and to keep all staff safe, but it also helps to protect the pallet racking systems. Forklifts can be tricky to navigate in packed spaces, and there is the risk of untrained staff damaging racks. Training can also include guidelines on stacking pallets so they are carefully positioned on the support beams.

- Optimizing layout: If your team is constantly bumping into the pallet racking systems, it may be time to look into warehouse design services and how you can optimize your warehouse’s layout. Ensuring the aisles are wide enough to avoid bumps helps maintain the racks and boosts operations.

- Using protective accessories: One of the best ways you can protect your pallet racks is by adding safety accessories, including column protectors, rack guards, guardrails and bollards. While these features add to the cost of the system, they ensure your racks have an added layer of protection and can add to overall workplace safety and compliance measures.

- Anchoring pallet racks: Anchoring pallet racks to the floor is a best practice for making the system more stable and less likely to collapse if an accident occurs. This practice becomes even more vital if seismic hazards are a concern in your location.

- Adhering to rack capacity: Always comply with the system’s load capacity and train staff not to overload racks to optimize storage or free up space. Overloading the system can affect the structure and stability of the racks, which is both a financial and safety concern.

- Reinforcing pallets: An effective way to extend the longevity of your pallet racking systems is to reinforce your racks with a wire mesh screen, pallet stop or similar solutions.

- Conducting regular checks: Regular warehouse inspections are important for checking the condition of your racking systems for safety, compliance and the longevity of your system.

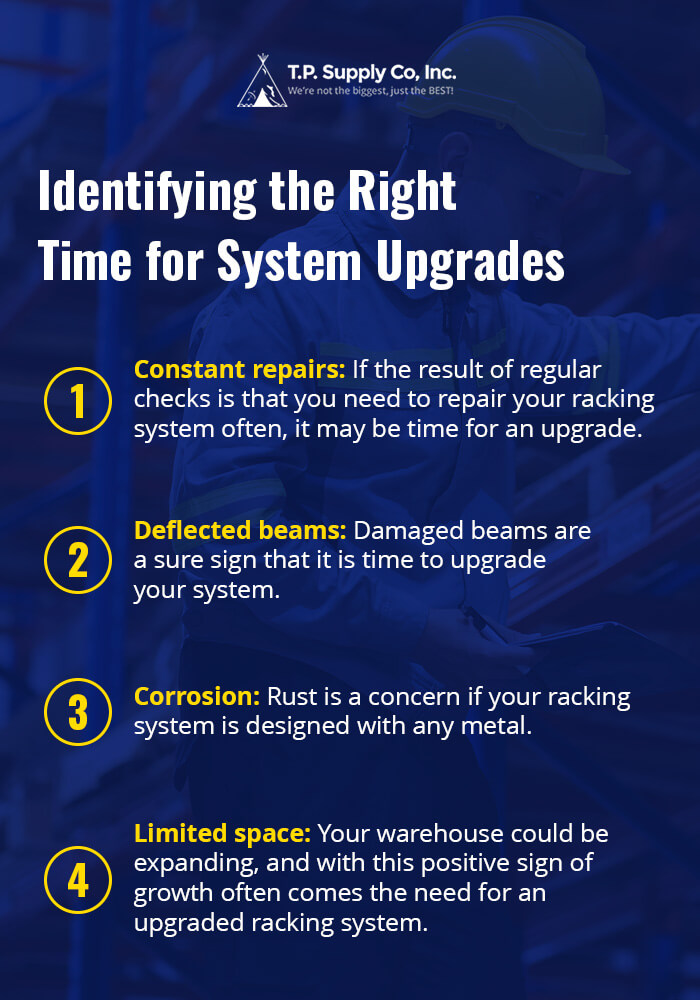

Identifying the Right Time for System Upgrades

A new, quality racking system should last for many years to come, especially if you are intentional about maintaining the racks. However, racking systems can age or become damaged, so knowing the signs of when it is time to get a new pallet racking system is vital:

- Constant repairs: If the result of regular checks is that you need to repair your racking system often, it may be time for an upgrade. Of course, occasional repairs are not usually a concern, but repeated repairs that don’t address faults effectively in the long term may cost more than upgrading the system and can lead to safety issues.

- Deflected beams: It is normal for beams to sometimes deflect, or bend under the weight of a load, even when staff follow the weight limit guidelines and even if the system was designed with sufficient support. However, the beam should not remain deflected when the weight is removed — if it stays deflected, it is damaged. Damaged beams are a sure sign that it is time to upgrade your system, as there is a risk of the system collapsing if the beams are overloaded.

- Corrosion: Rust is a concern if your racking system is designed with any metal. Rust indicates that the metal is weakening, and if this is the case, an upgrade is the only safe solution.

- Limited space: Another sure sign it’s time to upgrade your racking system is that your warehouse is running out of storage space! Your warehouse could be expanding, and with this positive sign of growth often comes the need for an upgraded racking system to accommodate your growing storage needs.

Navigating Pallet Racking Permits and Compliance Costs

Pallet racking permits make the workplace a safer environment. Most warehouses require a storage rack permit. To get a permit, racking systems need to comply with local zoning regulations, building codes and fire department safety standards. You may also need various types of permits depending on the size of your warehouse’s racking system. Obtaining permits often has associated fees, and it is best to consult with local authorities and industry experts to determine the type of racking permit your warehouse needs and the costs.

Additional Warehouse Racking Costs to Consider

Pallet racking pricing does climb as you upgrade your racking systems, whether that is through the cost per square foot for high-density racks or through accessories and custom options. Column guards and bumper posts protect individual racks in the warehouse from potential damage caused by forklifts. If you are operating in a tight storage space, column guards or bumper posts may be a particularly wise investment. You can expect the cost to vary from $50 to $300 each. Remember that pallet racking quotes may not include sales tax.

Get a Customized Quote for Pallet Racking

Many factors go into determining the cost of pallet racking systems, from the size of your system and the condition of the materials to how many accessories you need to add and who your supplier and installer is. Take out the guesswork by completing our customized quote form today. T.P. Supply can help you design a pallet racking system that fits your needs and your budget.

T.P. Supply offers the whole package, from estimates to delivery and installation. We send our own trusted employees — no outside contractors. Contact us today for more information about racking systems or to discuss your material handling equipment needs. You can also request a customized quote!