Types of Warehouse Stackers

Handling materials safely and efficiently is critical for proper warehouse functioning. Whether you need to store, move or distribute products, warehouse stackers help you complete these tasks. Equipment like pallet stackers allows you to move inventory and maintain the necessary organization for success.

There are multiple types of warehouse stackers and other pallet stacking equipment. Each type has its own pros and cons, from cost to operational capacity. Learning more about each type allows you to pick the best one for your warehouse products.

Here is an overview of what a stacker is and the different types of pallet stackers.

What Are Pallet Stackers?

These are tools designed for handling pallets or palletized items. Ideal for items of medium or large size, stackers use motors to help employees lift and handle products easily. In addition to moving pallets horizontally, stackers can also lift pallets to tall heights.

Their abilities make them ideal for warehouse storage, where workers organize pallets vertically to optimize space. You could also use pallet stackers for lifting pallets into cars or other vehicles.

Overall, they make it easier to handle warehouse products and are a more cost-effective option than forklifts and other similar equipment.

Which Pallet Stacker Is Right for Me?

Adding a pallet stacker to your tools is a great way to simplify product handling. However, there are various types of pallet stackers, so it’s sometimes tricky to discern which one is best for you.

Some stackers are better suited for different sized loads and conditions than others. Before choosing your stacker, you should think about how much it’ll carry and under what conditions, along with other considerations.

To pick the best type of pallet stacker, you can consider these questions:

- What weight will your pallet have to carry?

- How high will you lift the pallets?

- How often will you use the stacker?

- What conditions does your warehouse have?

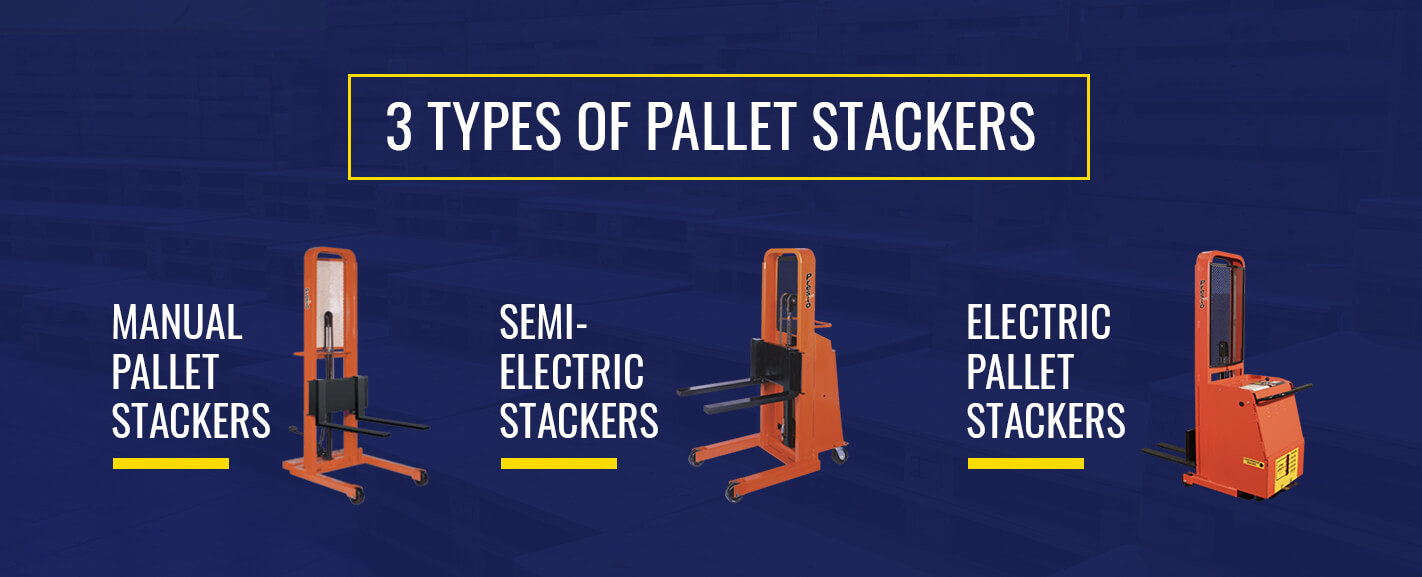

3 Types of Pallet Stackers

There are three major types of pallet stackers — manual, semi-electric and electric. Each style runs differently and has varying advantages. Learning about their different characteristics is the best way to choose the right stacker for your warehouse.

1. Manual Pallet Stackers

Manual pallet stackers are the most common type of warehouse stacker.

Instead of using an electronic control system, these stackers contain a hydraulic system that allows them to move and lift pallets. They have two wheels on the front of the stacker and one on the back that allows the machine to spin and turn. It also has a lever on the front.

Manual stackers are great for lifting pallets, but they require a little more work for usage than other types.

- How they work: To operate a manual pallet stacker, workers push the stacker to the required location. Once the user pushes the lever down, the hydraulic system activates. This system uses oil to transfer power throughout the stacker until it reaches the stacker forks. The oil gives them the capability to lift heavy amounts. Then, the worker starts cranking the handle, and the oil flows to the forks and pushes them up.

- Other types: Manual pallet stackers are great for lifting and transporting pallets, and they are available in other styles. For instance, there are manual types with larger platforms instead of forks, or some come with footgear that workers pump to raise the lift. Others have a hand crank for users to raise pallets. Either way, they all require manual help to lift pallets.

- Benefits: One of the significant benefits of manual stackers is they tend to be the most cost-effective. Without the extra costs of electronic controls, the stacker costs less to manufacture. So, a manual pallet stacker might be the best option if you’re watching your budget. Manual stackers can also fit into tight spaces, making them ideal for tighter warehouses.

2. Semi-Electric Stackers

Another type of warehouse stacker is a semi-electric stacker. This type uses a combination of manual and electric functions, creating a hybrid of both. This machine is best for transporting pallets across short distances and stacking them.

Because these are partially battery-powered pallet stackers, they rely on a battery’s power to work. Usually, the batteries last around a workday’s worth of work.

- How they work: Semi-electric stackers also use a hydraulic system to lift pallets, but it’s powered by batteries instead of oil. The batteries power a lift chain, which causes the forks to rise. Instead of cranking the stacker yourself, you can use electronic controls to operate the forks. The manual aspect of a semi-electric stacker is that a user has to move it to its position physically. It also contains a brake that workers can use to fully stop the machine when needed.

- Benefits: Because semi-electric pallet stackers have both electric and manual components, their cost is in the mid-range. It’s a great middle option in terms of price. Plus, a semi-electric stacker’s structure allows for rapid turns and movements. The foot brake helps you stop quickly, which is a great feature in a crowded warehouse.

3. Electric Pallet Stackers

The last major type of warehouse stacker is an electric pallet stacker, also known as a powered stacker. This type is also powered by batteries, along with an electric motor. Electric pallet stackers are the easiest to operate due to their entirely electronic controls. The electric motor makes the stacker move quickly and efficiently throughout your warehouse.

- How they work: These stackers run entirely on electric power. When a user switches the machine on, the battery transfers power to the electric motor. The energy in the engine converts to kinetic energy, which powers the hydraulic system, enabling the stacker to lift pallets. The stack has an additional motor that powers the wheels, so an operator can drive the stacker around instead of manually pushing it.

- Other types: Electric stackers are available in many styles. Some options have adjustable bases that make it easier to access higher levels. Another option for an electric stacker is known as a counterweight stacker. These stackers are designed to counterbalance the pallets’ weight with the other components of the machine. Counterbalance gives this type the ability to lift very heavy amounts to extreme heights.

- Benefits: Electric pallet stackers are typically the most expensive type. But, they’re usually the most capable of lifting heavy amounts. If your warehouse houses heavy products, the versatility and durability of an electric pallet stacker might be worth the extra cost. Because you don’t have to push them around, workers can navigate the warehouse more quickly. This speed raises your warehouse’s efficiency, which is always a positive for business.

Contact T.P. Supply Co for Pallet Stackers Today

Since 1979, T.P. Supply Co has provided storage products and material handling equipment for customers across the nation. Our extensive catalog of pallet stackers offers high quality and efficiency, ready for any of your warehouse needs.

Contact T.P. Supply Co today with any questions, or browse our pallet stackers to find the best fit for you.